CoreDEF™ STPs

The Red Jacket® CoreDEF™ Submersible Turbine Pumps are a revolutionary solution that sets a higher standard in the optimization of diesel exhaust fluid (DEF) pumping infrastructure. The CoreDEF™ STP is the entirely customizable DEF pump, designed for a complete range of light to heavy duty submersible DEF applications.

Various motor sizes, Quick Set® variable lengths, and the only adjustable pressure relief offering on the market, make the CoreDEF pump a flexible solution that can be tailored to maximize value, while controlling cost.

With included pre-assembly and factory leak testing, the CoreDEF submersible DEF pump cuts out the stress and time of installation and get you pumping sooner.

Model Portfolio for Varying Applications:

- The CoreDEF Series Portfolio holds the perfect motor size for your site.

Factory Leak Tested – Diesel Exhaust Fluid is extremely hard to contain and even harder to clean up:

- CoreDEF submersible DEF pumps are factory-tested to prevent any possibility of leaks in the field.

- Using a competitive pump may allow leaks and crystallization, seriously complicating serviceability.

Adjustable Pressure Relief Option – Enables the user to adjust line pressure between 20-45 PSI, making for painless post-installation flow rate tuning:

- Optimize operation with any dispenser.

- Avoid excessive nozzle squeeze.

- Prevent nozzle spit back.

Product Compatibility:

- Designed for DEF consisting of 32.5% urea and 67.5% de-ionized water.

- Liquid Quality Compliance: The submersible pump and supplied components satisfy the ISO 22241 standard for DEF quality.

Product Compatibility:

- Durable stainless-steel construction for longevity and DEF compatibility.

- Capacitor stored in control box for simple installation, easy access and improved operation environment

- Pressure relief valve allows for continuous running and protects motor when nozzles are idle.

- Capable of 30 start/stop cycles per hour to prevent motor burnout.

- Portfolio of motors available to meet global power requirements.

- Check Valve available to maintain line pressurization during idle periods.

| Fuel Compatibility |

*consisting of 32.5% urea and 67.5% de-ionized water |

| Motor Sizing |

|

| Line Pressure Relief Options |

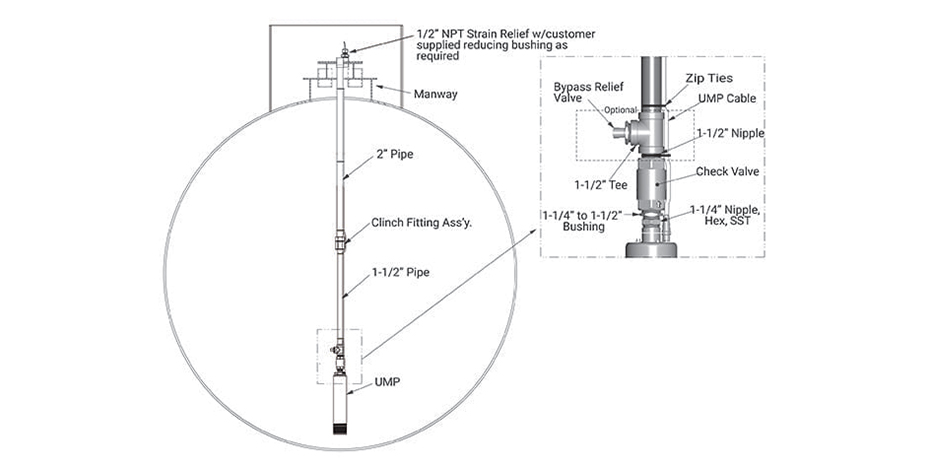

Fixed Pressure Relief (In Tank)

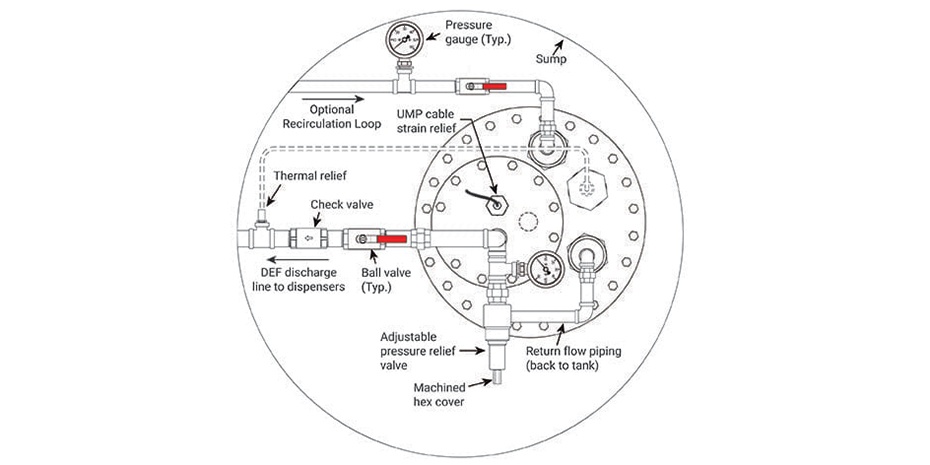

Adjustable Pressure Relief (In Sump)

|

| Hardware Construction |

Column Pipe:

Impellers and Diffusers:

Pump and Motor Side Mechanical Seals:

Elastomers:

|

| Protective Coatings | N/A |

| DEF Fluid - Operating Temperature Range | -11°C to +40°C |

| Installation Depth Range |

Quick Set (Adjustable Length)

**Assumes 3/4 HP |

| Check Valve Compatibility | CoreDEF Inline Stainless Steel Check Valve: 410881-001 |

| Agency |

Agency Listings:

|