The most efficient way to pump LPG

Maintain optimum flow rates quietly to enhance customer experience, pump LPG greater distances, gain flexibility in station design and eliminate vapour lock conditions.

Lower installation and maintenance costs

Lowest total cost of ownership with simpler installation, lower maintenance costs and less power consumption than alternative solutions.

Proven quality and durability

Solid construction using high quality components means the Premier family of submersible pumps has built a reputation for reliability and durability in thousands of LPG applications worldwide.

Key benefits:

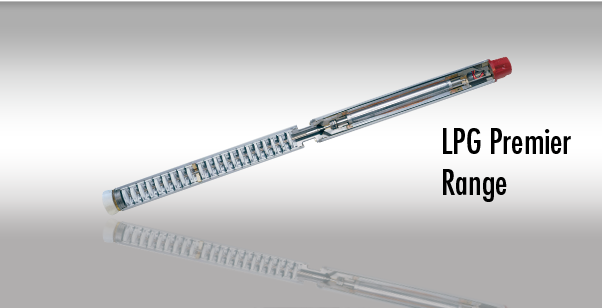

Red Jacket Premier

- Entry level option for lower flowrate requirements

- Flowrate 70 litres per minute at 700 kPa.

Red Jacket Premier MidFlow

- For LPG refuelling applications with low to intermediate flow requirements

- Flowrate 100 litres per minute at 700 kPa.

Red Jacket Premier HiFlow

- For higher capacity installations such as commercial vehicle fuelling facilities and bottle filling plants

- Flowrate 150 litres per minute at 700 kPa.

Mag-XL Probe

| Model | Premier | Premier MidFlow | Premier HiFlow | |

|

Flow rate at 700 kPa |

70 Litres/min |

100 Litres/min |

150 Litres/min |

|

|

Flow rate at Maximum Efficiency |

70 Litres/min at 680 kPa |

130 Litres/min at 580 kPa |

130 Litres/min at 810 kPa |

|

|

Flow rate at 400 kPa |

100 Litres/min |

170 Litres/min |

190 Litres/min |

|

|

Motor |

VAC |

380-415 |

380-415 |

380-415 |

Hz |

50 |

50 |

50 |

|

HP |

3 |

3 |

5 |

|

kW |

2.2 |

2.2 |

3.7 |

|

|

Pump stages |

21 |

17 |

24 |

|

|

Unit Length (mm) |

1506 |

1506 |

1896 |

|

|

Unit Weight (kg) |

39 |

39 |

48 |

|